Aluminum Round Pipe

Extruded aluminum pipe is stocked in both seamless and structural (port-hole die).

Aluminium pipe is used in pressure or structural application.

These Aluminium Pipe are light weight, excellent corrosion resistance, and the ability to transmit heat rapidly are only a few of the benefits of aluminum pipes.

Product Details

Product introduction

There are 2 types of Aluminium Pipe:

1) Aluminium Extruded Pipe: Aluminium Extruded Pipe, formed by hot extruding through a die, is available as a seamless or structural grade product.

2) Aluminium Drawn Pipe: Aluminium Drawn Pipe is a seamless extruded Pipe is brought to final size by drawing through a die.

Technical data

| Aluminium Alloy | ASTM B210, ASTM B234, ASTM B241, ASTM B483; GB/T 6893-2000, GB/T 4437-2000: JIS H4080-2006 |

| Aluminium Pipe American Specifications: | ASTM B210 drawn, ASTM B241 extruded, AMS 4173, AMS 4080, AMS 4082, AMS4083, WW-T-700/6 |

| Aluminium Pipe British Specifications | H20, HE 20 |

| Material | 1060, 1200, 1100, 2024, 2124, 3003, 3004, 5050, 5083, 5154, 5454, 5652, 5086, 5056, 5754, 6061, 6062, 6063, 7075, etc. |

| Aluminium Pipe Standard | ASTM, ASME, AMS, ASTM B210M, GB/T 3191, JIS H4040, ASTM B210, AMS QQ-A-200/9 |

| Aluminium Pipe Temper | O, H12, H14, H16, H18, H22, H24, H26, H32, H112 |

| Aluminium Pipe Form | Aluminium extruded, seamless, drawn and coiled Pipe in Black & Bright Finish |

| Aluminium Pipe Sizes | 1/8″ – 16″ (3mm – 2500mm) OD .020″ – 2″ (.2mm – 150mm) wall (1m-12m) Length |

| Machinability | Fair |

| Weldability | Good |

| Corrosion Resistance | Good |

| Aluminium Pipe | Bright, Polish & Black |

| Aluminium Pipe Surface | Anodized, Oxidation, electrophoresis coating, fluorine carbon spraying, powder coating, wood grain transfer printing, mechanical drawing, mechanical polishing, sand blasting, Polished, hair line, brush, Mill finished, Bright finish, paper interleaved |

| Surface treatment | Nature, Black painting, Transparent oil, rust-proof black oil or hot-dip galvanized |

| Aluminium Pipe Delivery Time | 10-30 days after receiving the prepayment |

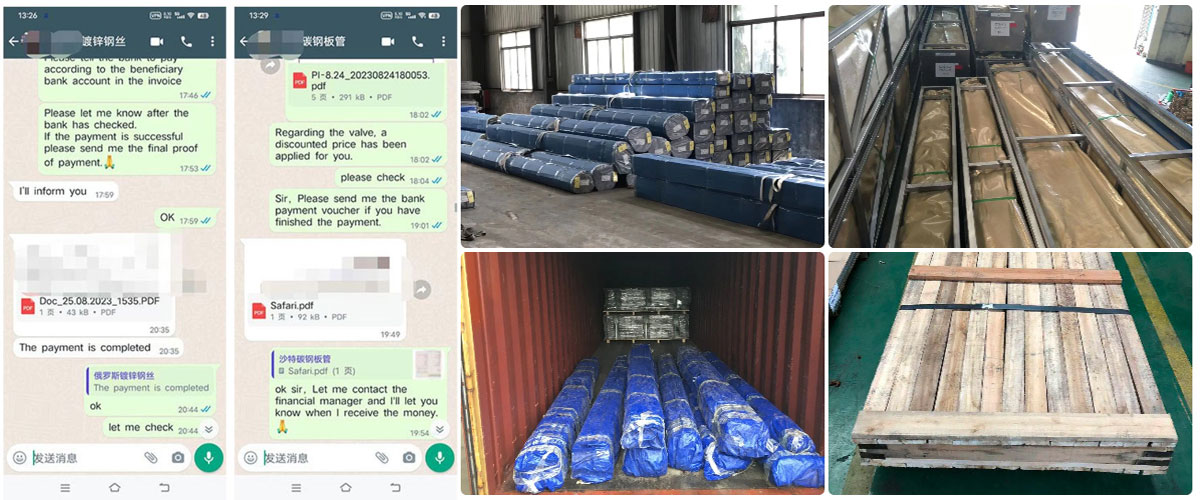

| Aluminium Pipe Packaging Details | Export standard package: bundled wooden box, suit for all kinds of transport or be required. |

| ASTM B210 Alloy Pipe Outer packing | Export standard, wooden pallet |

| Here are 6 different types of finishes for extruded aluminum Pipe: |

|

| Applications | Bicycle Parts, aircraft ducting, wheelchair frames, telescopes, machined bushes, air cylinders |

| Aluminum Pipe Features: | |

|---|---|

| 1.Materials | 7001-T6/T9, 7075-T9 alloy |

| 2.High strengh | 660Mpa |

| 3.Light weight | Aluminum alloy is lighter weight |

| 4.Tightness tolerance | a) Inner diameter:±0.02mm b) Outer diameter:±0.02mm |

| 5.Weight | ±0.5% |

| 6.Straightened to 0.12mm | |

Aluminium Pipe Mechanical Properties

Aluminum Alloy Heat Treatment Temper Designations for Pipes

Basic Aluminum Heat Treatment Designations

F As Fabricated

O Annealed

H Strain Hardened

W Solution Heat Treated

T Solution Heat Treated

Heat Treating T Temper Codes for Aluminium Pipe

T1 – Cooled from an elevated temperature shaping process and naturally aged to a substantially stable condition.

T2 – Cooled from an elevated temperature shaping process, cold worked, and naturally aged to a substantially stable condition.

T3 – Solution heat treated, cold worked, and naturally aged to a substantially stable condition.

T4 – Solution heat treated, and naturally aged to a substantially stable condition.

T5 – Cooled from an elevated temperature shaping process then artificially aged.

T6 – Solution heat treated then artificially aged.

T7 – Solution heat treated then overaged/stabilized.

T8 – Solution heat treated, cold worked, then artificially aged.

T9 – Solution heat treated, artificially aged, then cold worked.

T10 – Cooled from an elevated temperature shaping process, cold worked, then artificially aged.

Additional digits may be used after the first T temper digit to indicate subsequent stress relieving by processes such as stretching, compressing, or a combination.

H Temper Strain Hardening Codes for Aluminium Pipe

H1 – Strain hardened only

H2 – Strain hardened and partially annealed

H3 – Strain hardened and stabilized

H4 – Strain hardened and lacquered or painted. This assumes that thermal affects from the coating process affect the strain hardening; seldom encountered.

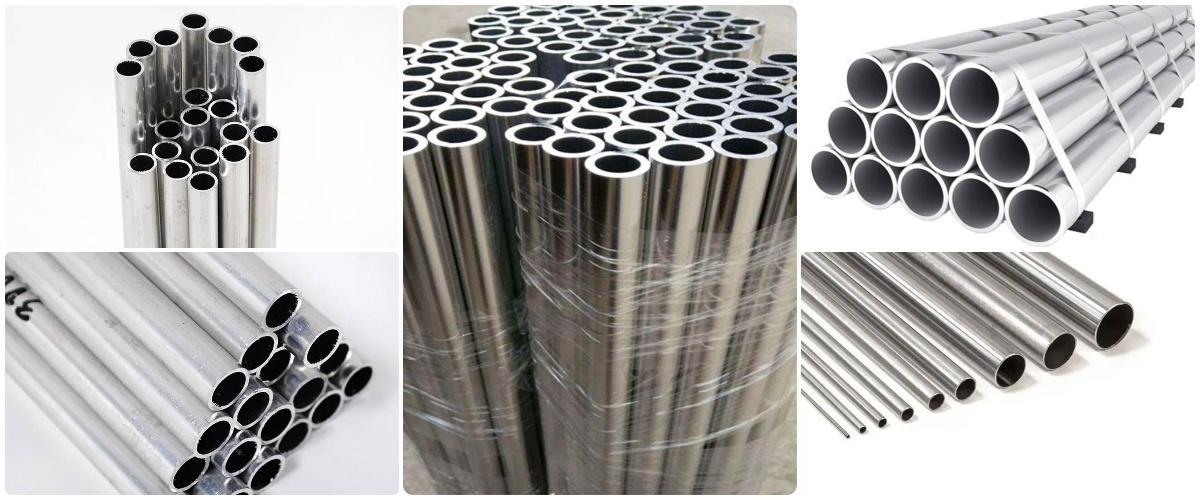

Product Picture

Packaging and transportation&Customer feedback

Product Certificate

Shandong Chengshun Metal Materials Co., Ltd.is a comprehensive company dealing in high-quality steel products, with a superior geographical location and very convenient transportation. The company has a complete and scientific quality system, and has been recognized by the industry for its integrity, strength and product quality. Always adhere to the tenet of high quality, low cost, fast pace and excellent service. Our products have passed the "IS09001" qualtly system cerification, own CE cerificate and SGS test report.

APPLICATION FIELD

Our main manufactures are stainless steel, galvanized steel, carbon steel and etc. That apply to engineering, coal mine, textile, electric power, boiler, machinery, We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. We′re pleased to get your Inquiry and we will come back to as soon as possible.

mechanical

power plant

chemical plant

Oil Pipelines

Natural Gas Pipeline

refrigeration equipment

boiler plant

Chemical plant

Water pipes

Bearing

RELATED PRODUCTS

Get a Free Quote