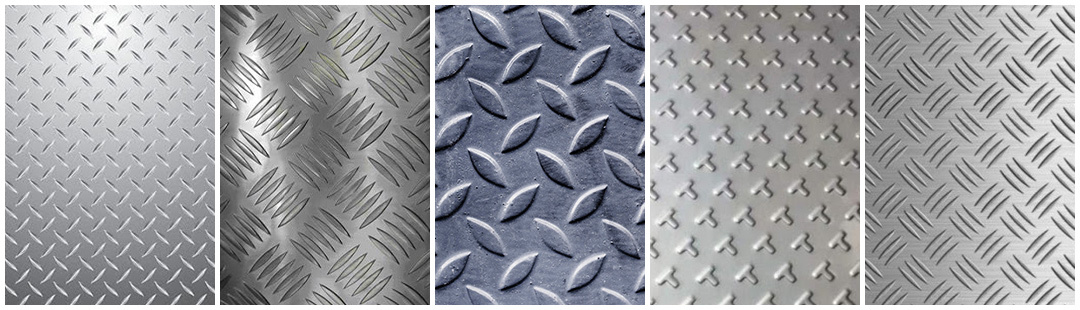

Stainless Checker Plate

Product Details

| Name | Stainless Checker Plate |

| Thickness | 0.3mm-150mm |

| Width | 1000,1219mm,1250,1500mm,1530,1800mm,2000mm,2200mm etc. |

| Length | 2000,2438,3000,6000 etc. |

| Standard | ASTM JIS AISI GB DIN EN |

| Surface Finished | BA, 2B,NO.1, NO.4, 4K, HL ,8K |

| Certification | ISO, SGS, BV |

| Technique | Hot rolled or cold drawing |

| Edge | Mill Edge /Slit Edge |

| Quality | SGS Inspection |

| Main market | Asia/Europe/ South America |

| Delivery time | Within 7-10 Working Days |

| Payment Terms | T/T L/C and Western Union etc. |

| Finish | Description | Thickness (mm) | Width (mm) |

| 2B | Smooth finish, reflective grey sheen.Most widely used surface finish. | 0.55 | 914 & 1219 |

| Bright Annealed (BA) | Cold rolled, annealed in a controlled atmosphere to retain a highly reflective finish. | 0.70 | 914 & 1219 |

| Dull Polish (DP) | Selected for ease of cleaning, brushed look, non-reflective, used extensively in the catering industry, also push plates and kickplates. | 0.90 | 750, 914 & 1219 |

| Hot Rolled (HR) | Scaled finish, ideal if surface finish is not a key concern. | 1.20 | 750, 914, 1050, 1219 & 1500 |

| No.1 | Finished by hot-rolling,annealing and pickling, characterized by white pickled surface | 1.50 | 914, 1219 & 1500 |

| HL | finished by continuous liner polishing | 1.60 | 914, 1219 & 1500 |

| No.4 | polishing with No.150 to No.180 mesh | 2.00 | 914, 1219 & 1500 |

| No.8 | a mirror-like reflective surface by polishing | 2.50 | 914, 1219 & 1500 |

Chemical Composition

| Grade | W.nr | DIN | C | Cr | Ni | Mo | N | Mn | Other |

| 201/201L | - | - | 0.15 | 16.0-18.0 | 3.50/5.50 | - | 0.25 | 5.5-7.5 | 0.25N |

| 301 | 1.4310 | X12CrNi177 | 0.15 | 16.0-18.0 | 6.00/8.00 | - | 0.1 | 2 | - |

| 303 | 1.4305 | X12CrNi188 | 0.15 | 17.0-19.0 | 8.00/10.00 | 0.60* | 0.1 | 2 | - |

| 304 | 1.4350 | X5CrNi189 | 0.08 | 18.0-20.0 | 8.00/10.50 | - | 0.1 | 2 | - |

| 304L | 1.4306 | X2CrNi1911 | 0.03 | 18.0 - 20.0 | 8.0-12.0 | - | 0.1 | 2 | - |

| 321 | 1.4541 | X10CrNiTi189 | 0.08 | 17.0-19.0 | 9.0-12.0 | - | 0.1 | 2 | Ti 5x(C+N) |

| 316 | 1.4435 | X2CrNiMo1812 | 0.08 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.1 | 2 | - |

| 316L | 1.4436 | X2CrNiMo1812 | 0.03 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | 0.1 | 2 | - |

| 309 | 1.4828 | X15CrNiSi2012 | 0.08 | 22.0-24.0 | 12.0-15.0 | - | - | 2 | - |

| 310S | 1.4845 | X12CrNi2521 | 0.08 | 24.0-26.0 | 19.0-22.0 | - | - | 2 | - |

| 904L | 1.4539 | X2NiCrMoCu25205 | 0.02 | 19.0-23.0 | 23.0-28.0 | 4.00-5.00 | 0.1 | 2 | - |

| 409 | 1.4512 | X6CrTi12 | 0.03 | 10.5-11.7 | 0.5 | - | 0.03 | - | Ti 6x(C+N) to .50 |

| 430 | 1.4016 | X8Cr17 | 0.12 | 16.0-18.0 | 0.75 | - | - | 1 | - |

| 439 | 1.4510 | X3CrTi17 | 0.03 | 17.0-19.0 | 0.5 | - | 0.03 | 1 | Ti [0.20+4(C+N)] to 1.10Al .15 max. |

| 2205 | 1.4462 | X2CrNiMoN2253 | 0.03 | 22.0-23.0 | 4.5-6.5 | 3.0-3.5 | 0.14-0.20 | 2 | - |

| 2507 | 1.4410 | X2CrNiMoN2574 | 0.03 | 24.0-26.0 | 6.0-8.0 | 3.0-5.0 | 0.24-0.32 | 1.2 | - |

| s32760 | 1.4501 | X2CrNiMoCuWN | 0.03 | 24.0-26.0 | 6.0-8.0 | 3.0-4.0 | 0.20-0.30 | 1 | W 0.50-1.00 |

| 1.4529 | - | X1NiCrMoCuN | 0.02 | 20 | 25 | 6.5 | 0.15 | - | Cu 1.0 |

| 1.4362 | - | X2CrNiN23-4 | 0.02 | 23 | 4.8 | 0.3 | - | - | - |

| 254SMO | 1.45475 | 42CrMo4 | 0.01 | 20 | 18 | 6.1 | 0.02 | - | - |

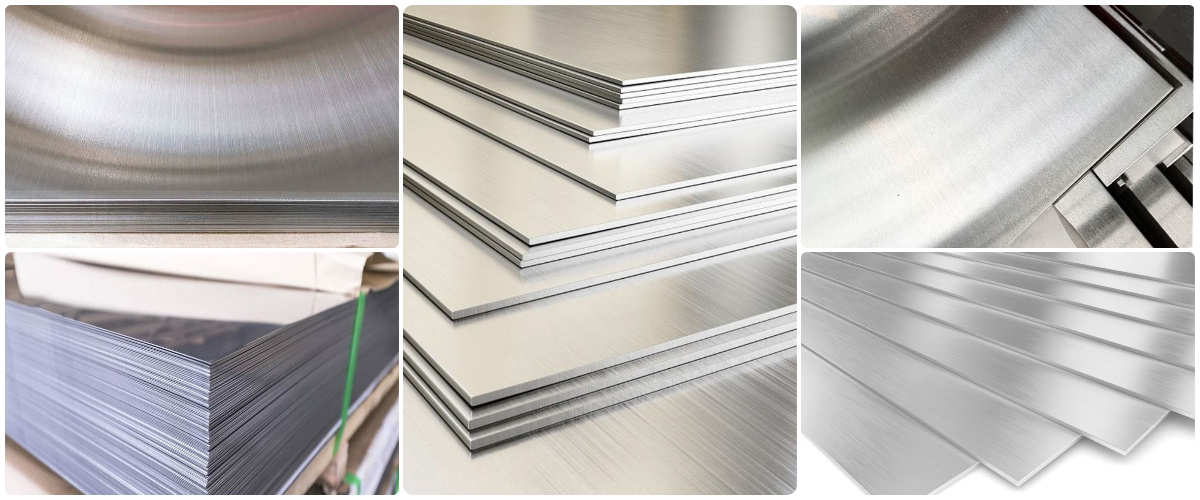

Product Presentation

Benefits:

- Corrosion Resistance: Stainless steel sheets are highly resistant to corrosion, rust, and staining, ensuring longevity and durability in harsh environments.

- Strength: They offer high strength-to-weight ratio, providing structural integrity and support in various applications.

- Hygienic: Stainless steel sheets are easy to clean and maintain, making them ideal for industries with stringent hygiene standards like food processing and medical equipment manufacturing.

- Aesthetic Appeal: They have a sleek and modern appearance, enhancing the visual appeal of architectural elements and design features.

Manufacturing Techniques:

- Cold Rolling: Stainless steel sheets are often produced through cold rolling processes, where stainless steel coils are compressed between rollers at room temperature to achieve desired thickness and surface finish.

- Hot Rolling: In hot rolling, stainless steel ingots are heated and passed through rollers to reduce thickness and shape the sheets. This process is suitable for thicker sheets and can achieve specific mechanical properties.

Applications:

- Construction: Stainless steel sheets are widely used in construction for roofing, cladding, and decorative elements due to their durability, corrosion resistance, and aesthetic appeal.

- Automotive Industry: They find applications in automotive manufacturing for body panels, exhaust systems, and trim components due to their corrosion resistance and lightweight nature.

- Kitchen Equipment: Stainless steel sheets are commonly used in the production of kitchen appliances and equipment such as countertops, sinks, and backsplashes due to their hygienic properties and easy-to-clean surfaces.

- Medical Equipment: They are utilized in the medical industry for manufacturing surgical instruments, medical devices, and equipment due to their biocompatibility, corrosion resistance, and ease of sterilization.

- Chemical Processing: Stainless steel sheets are employed in chemical processing plants for tanks, vessels, and piping systems handling corrosive chemicals and fluids.

- Manufacturing: They are used in various manufacturing processes for machinery, equipment enclosures, and fabrication due to their strength, versatility, and ease of machining.

Suitable Industries:

- Architecture and Design: Stainless steel sheets are favored in architectural and interior design projects for their aesthetic appeal, durability, and versatility in creating modern and innovative spaces.

- Automotive Manufacturing: They are essential in the automotive industry for producing lightweight and corrosion-resistant components, contributing to vehicle performance and longevity.

- Food and Beverage Industry: Stainless steel sheets are indispensable in food processing and beverage production for their hygienic properties, corrosion resistance, and ease of cleaning.

- Medical and Healthcare: They are crucial in the medical and healthcare sectors for manufacturing sterile and corrosion-resistant equipment and devices, ensuring patient safety and hygiene standards are met.

- Chemical Processing: Stainless steel sheets are vital in chemical processing plants for their resistance to corrosion and chemical compatibility, ensuring safe handling of corrosive substances and fluids.

In summary, stainless steel sheets offer a combination of corrosion resistance, strength, hygiene, and aesthetic appeal, making them essential materials in various industries including construction, automotive, food processing, and healthcare.

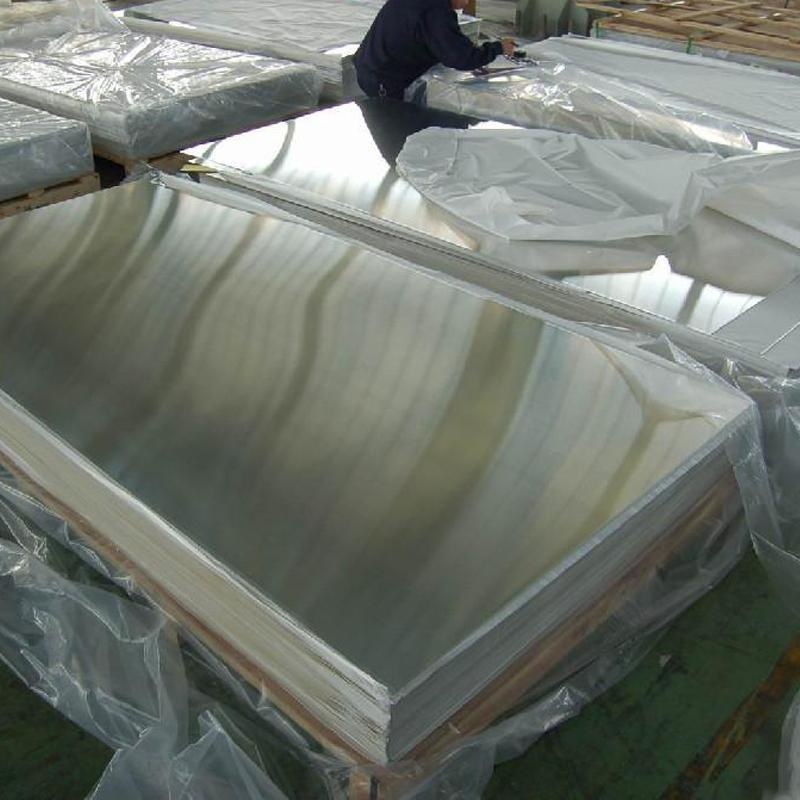

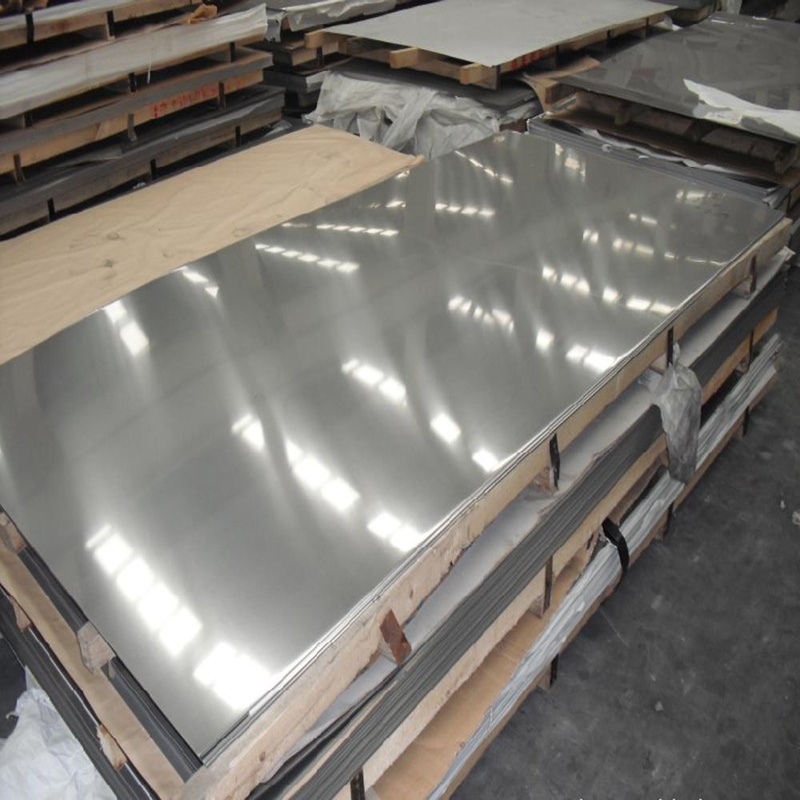

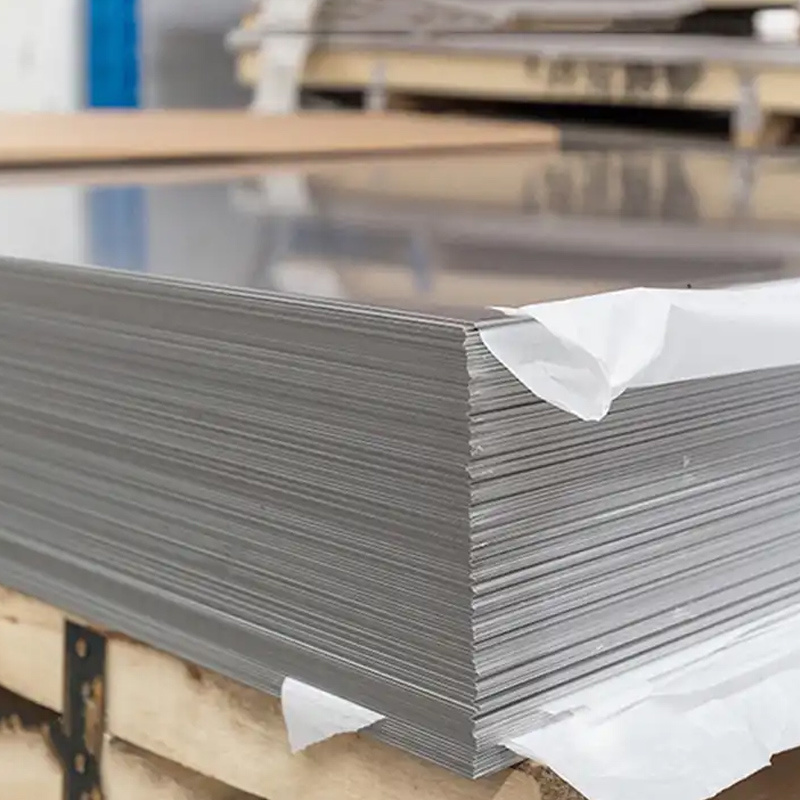

Product Picture

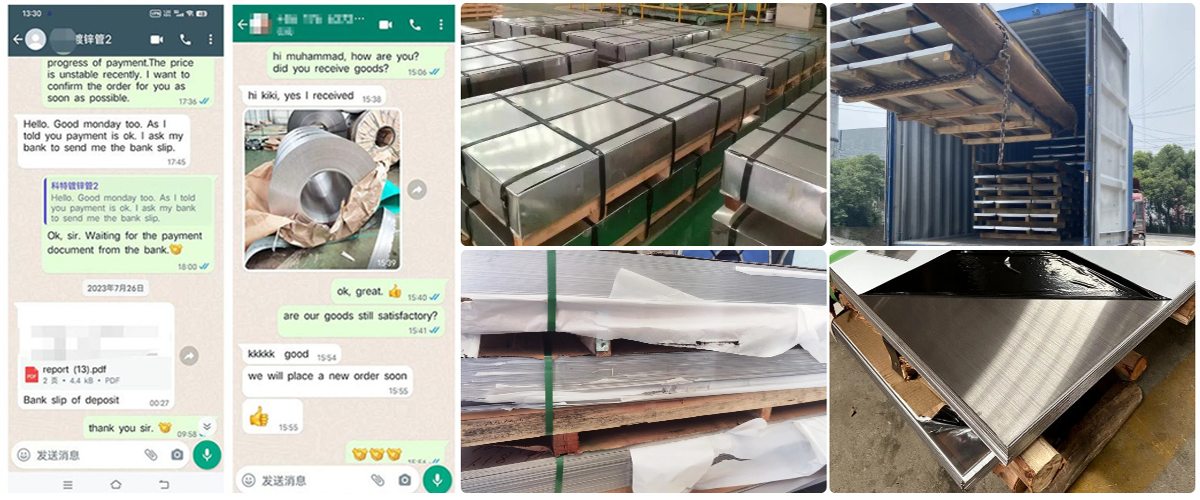

Packaging and transportation&Customer feedback

Product Certificate

Shandong Chengshun Metal Materials Co., Ltd.is a comprehensive company dealing in high-quality steel products, with a superior geographical location and very convenient transportation. The company has a complete and scientific quality system, and has been recognized by the industry for its integrity, strength and product quality. Always adhere to the tenet of high quality, low cost, fast pace and excellent service. Our products have passed the "IS09001" qualtly system cerification, own CE cerificate and SGS test report.

APPLICATION FIELD

Our main manufactures are stainless steel, galvanized steel, carbon steel and etc. That apply to engineering, coal mine, textile, electric power, boiler, machinery, We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. We′re pleased to get your Inquiry and we will come back to as soon as possible.

mechanical

power plant

chemical plant

Oil Pipelines

Natural Gas Pipeline

refrigeration equipment

boiler plant

Chemical plant

Water pipes

Bearing

RELATED PRODUCTS

Get a Free Quote