ASTM A106 Carbon Steel Pipe

Product Details

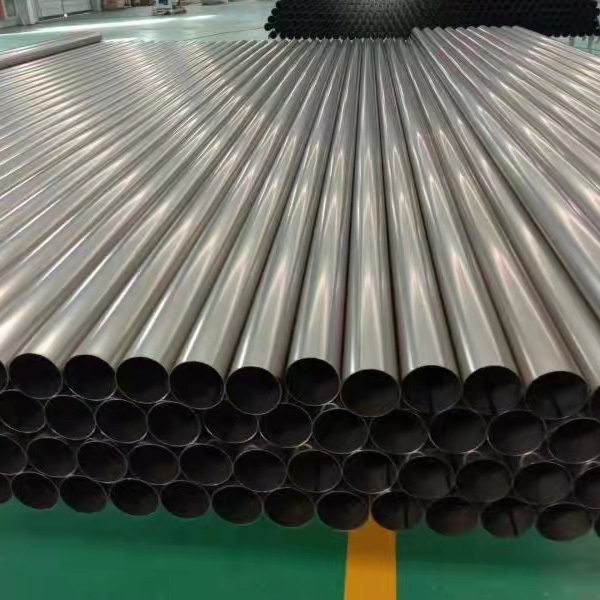

A106 Steel Pipe Description

A106 steel pipe is a low carbon steel pipe whose main components are carbon, silicon, manganese and small amounts of chromium, copper, nickel and molybdenum. It is a seamless steel pipe suitable for transporting liquids and gases in high temperature and high pressure environments. The manufacturing process of A106 steel pipe usually includes steps such as hot rolling, cold drawing and cold working. During these processes, the internal structure of the pipe is made tighter through heat and pressure treatment, thereby improving its strength and corrosion resistance. A106 steel pipe can be used in many different fields, such as oil, natural gas, chemical industry, electric power, shipbuilding, aerospace, etc...

Product Parameters

|

Product Name |

A106 Steel Pipe |

|

|

Standard |

EN/DIN/JIS/ASTM/BS/ASME/AISI etc. |

|

|

Outer Diameter |

Seamless: 1/4"-36" |

Welding: 21.3mm-3620mm |

|

Round Tube: 1/2"-10" |

Square Tube/Rectangular Tube: 15x15mm-400x600mm |

|

|

Wall Thickness |

Seamless: 1.25mm-50mm |

Welding: 1.65mm-65mm |

|

Length |

3-12 meters, Support customization |

|

|

Surface Process |

Bright, Polished, Black |

|

|

Other Services |

Machining(cnc), Centerless Grinding(cg), Heat Treatment, Annealing, Pickling, Polishing, Rolling, Forging, Cutting, Bending, Small Machining, etc. |

|

Chemical Composition

|

A106 |

C |

Mn |

P |

S |

Si |

Cr |

Cu |

Mo |

Ni |

V |

|

Grade A |

0.25 |

0.27-0.93 |

0.035 |

0.035 |

0.10 |

0.40 |

0.40 |

0.15 |

0.40 |

0.08 |

|

Grade B |

0.30 |

0.29-1.06 |

0.035 |

0.035 |

0.10 |

0.40 |

0.40 |

0.15 |

0.40 |

0.08 |

|

Grade C |

0.35 |

0.29-1.06 |

0.035 |

0.035 |

0.10 |

0.40 |

0.40 |

0.15 |

0.40 |

0.08 |

Mechanical Properties

|

A106 |

Grade A |

Grade B |

Grade C |

|

Tensile Strength min. psi |

48,000 |

60,000 |

70,000 |

|

Yield Strength min. psi |

30,000 |

35,000 |

40,000 |

Scope of Application

ASTM A106 seamless pressure pipe (also known as ASME SA106 pipe) is commonly used in the construction of oil and gas refineries, power plants, petrochemical plants, boilers and ships. These pipes must transport fluids and gases with high temperature and pressure levels.

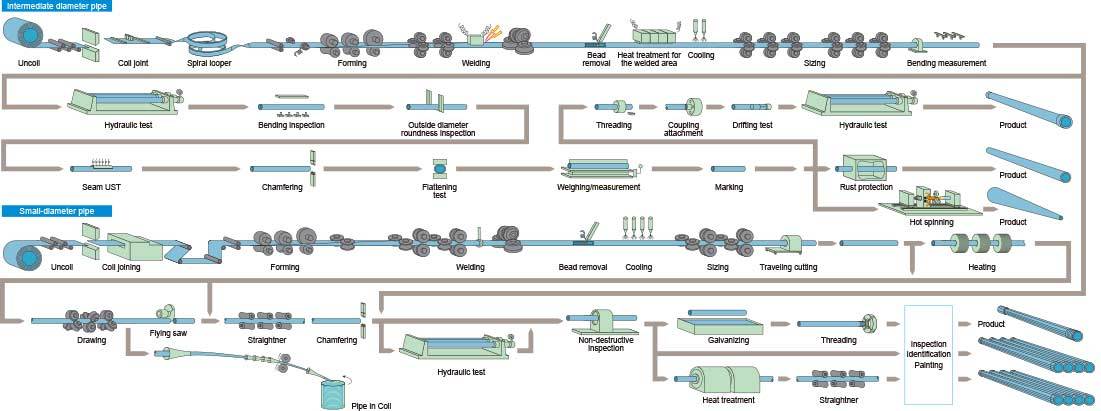

Process

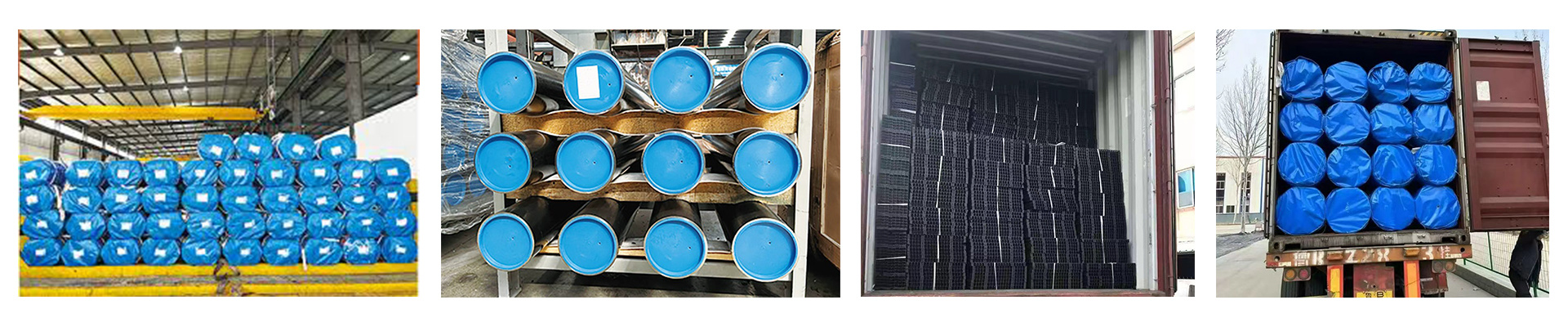

Packing

| Bundled package | Wooden box package |

|

On bundle of steel tube shall be the same in batch number, steel grade and specification.the rest of tubing less than one bundle should be tied into small bundles. The weight of each bundle should be less than 50kg.The max weight cannot exceed 80kg of the bundle If there are special requirements. When the length of the steel tube is greater than or equal to 6m, with at least 8 strapping bands for each bundle, divided into 3 groups and 3-2-3. When the length of the steel tube is less than 6m, and each bundle is tied at least 5 knots and divided into 3 groups, which are 2-1-2. When the length of the tube is greater than or equal to 3m, and each bundle is tied with at least 3 bands, divided into 3 groups, 1-1-1 showed below |

The wooden box is suitable for cold rolling or cold drawing seamless steel tube, polished hot rolled stainless steel tube. When the outer diameter of steel pipe is greater than or equal 10mm, the maximum weight of the container should be 50kg. When the outer diameter of steel pipe is less than or equal 10mm, the maximum weight of the container should be 30kg. |

Factory Tour

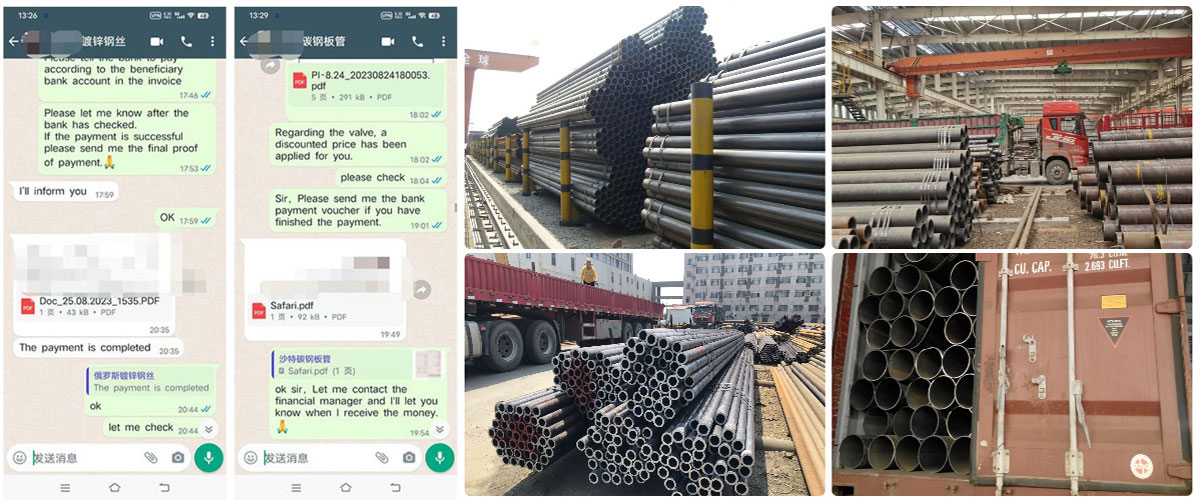

Packaging and transportation&Customer feedback

Product Certificate

Shandong Chengshun Metal Materials Co., Ltd.is a comprehensive company dealing in high-quality steel products, with a superior geographical location and very convenient transportation. The company has a complete and scientific quality system, and has been recognized by the industry for its integrity, strength and product quality. Always adhere to the tenet of high quality, low cost, fast pace and excellent service. Our products have passed the "IS09001" qualtly system cerification, own CE cerificate and SGS test report.

APPLICATION FIELD

Our main manufactures are stainless steel, galvanized steel, carbon steel and etc. That apply to engineering, coal mine, textile, electric power, boiler, machinery, We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. We′re pleased to get your Inquiry and we will come back to as soon as possible.

mechanical

power plant

chemical plant

Oil Pipelines

Natural Gas Pipeline

refrigeration equipment

boiler plant

Chemical plant

Water pipes

Bearing

RELATED PRODUCTS

Get a Free Quote