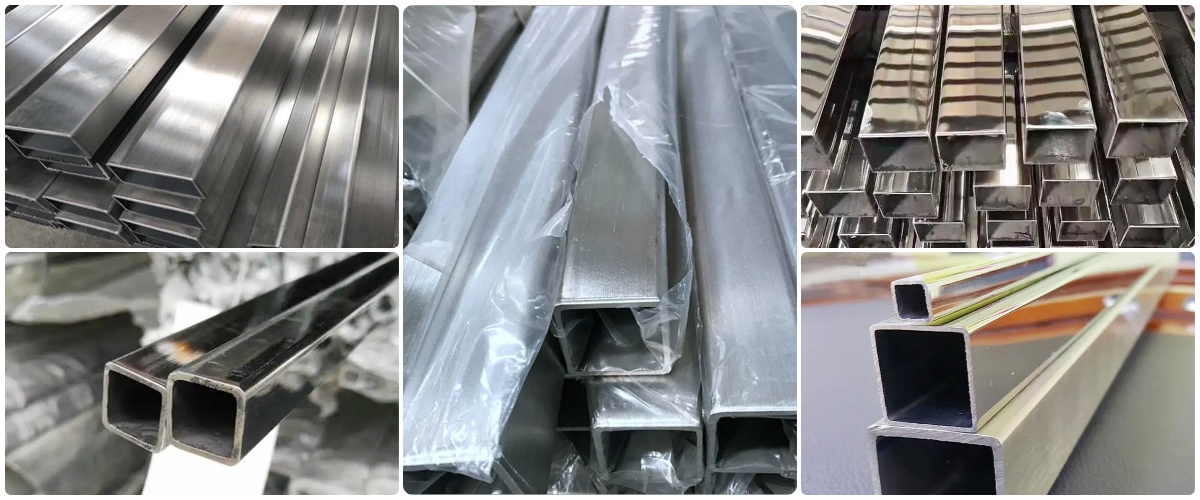

304 STAINLESS STEEL SQUARE PIPE

Product Details

| Name | Stainless Steel Pipe |

| Thickness | 0.24-3mm |

| Outer diameter | 8-219mm |

| Length | 1-6m or according to customer's request |

| Standard | ASTM JIS AISI GB DIN EN |

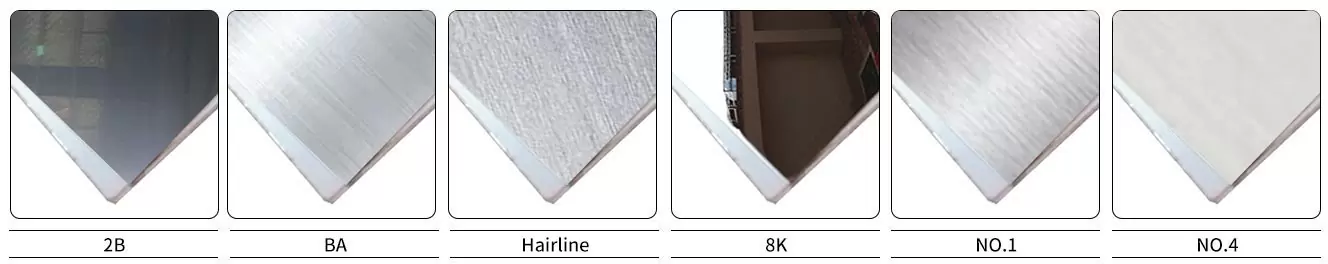

| Surface Finished | BA, 2B,NO.1, NO.4, 4K, HL ,8K |

| Certification | ISO, SGS, BV |

| Technique | Hot rolled or cold drawing |

| Edge | Mill Edge /Slit Edge |

| Quality | SGS Inspection |

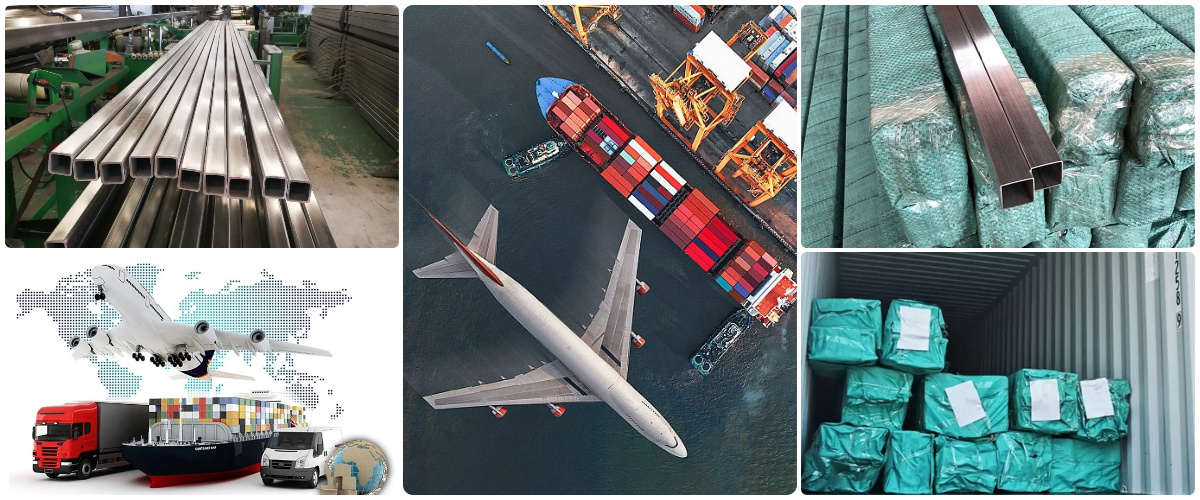

| Main market | Asia/Europe/ South America |

| Delivery time | Within 7-10 Working Days |

| Payment Terms | T/T L/C and Western Union etc. |

| Finish | Description | Thickness (mm) | Width (mm) |

| 2B | Smooth finish, reflective grey sheen.Most widely used surface finish. | 0.55 | 914 & 1219 |

| Bright Annealed (BA) | Cold rolled, annealed in a controlled atmosphere to retain a highly reflective finish. | 0.70 | 914 & 1219 |

| Dull Polish (DP) | Selected for ease of cleaning, brushed look, non-reflective, used extensively in the catering industry, also push plates and kickplates. | 0.90 | 750, 914 & 1219 |

| Hot Rolled (HR) | Scaled finish, ideal if surface finish is not a key concern. | 1.20 | 750, 914, 1050, 1219 & 1500 |

| No.1 | Finished by hot-rolling,annealing and pickling, characterized by white pickled surface | 1.50 | 914, 1219 & 1500 |

| HL | finished by continuous liner polishing | 1.60 | 914, 1219 & 1500 |

| No.4 | polishing with No.150 to No.180 mesh | 2.00 | 914, 1219 & 1500 |

| No.8 | a mirror-like reflective surface by polishing | 2.50 | 914, 1219 & 1500 |

Chemical Composition

| Grade | W.nr | DIN | C | Cr | Ni | Mo | N | Mn | Other |

| 201/201L | - | - | 0.15 | 16.0-18.0 | 3.50/5.50 | - | 0.25 | 5.5-7.5 | 0.25N |

| 301 | 1.4310 | X12CrNi177 | 0.15 | 16.0-18.0 | 6.00/8.00 | - | 0.1 | 2 | - |

| 303 | 1.4305 | X12CrNi188 | 0.15 | 17.0-19.0 | 8.00/10.00 | 0.60* | 0.1 | 2 | - |

| 304 | 1.4350 | X5CrNi189 | 0.08 | 18.0-20.0 | 8.00/10.50 | - | 0.1 | 2 | - |

| 304L | 1.4306 | X2CrNi1911 | 0.03 | 18.0 - 20.0 | 8.0-12.0 | - | 0.1 | 2 | - |

| 321 | 1.4541 | X10CrNiTi189 | 0.08 | 17.0-19.0 | 9.0-12.0 | - | 0.1 | 2 | Ti 5x(C+N) |

| 316 | 1.4435 | X2CrNiMo1812 | 0.08 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.1 | 2 | - |

| 316L | 1.4436 | X2CrNiMo1812 | 0.03 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | 0.1 | 2 | - |

| 309 | 1.4828 | X15CrNiSi2012 | 0.08 | 22.0-24.0 | 12.0-15.0 | - | - | 2 | - |

| 310S | 1.4845 | X12CrNi2521 | 0.08 | 24.0-26.0 | 19.0-22.0 | - | - | 2 | - |

| 904L | 1.4539 | X2NiCrMoCu25205 | 0.02 | 19.0-23.0 | 23.0-28.0 | 4.00-5.00 | 0.1 | 2 | - |

| 409 | 1.4512 | X6CrTi12 | 0.03 | 10.5-11.7 | 0.5 | - | 0.03 | - | Ti 6x(C+N) to .50 |

| 430 | 1.4016 | X8Cr17 | 0.12 | 16.0-18.0 | 0.75 | - | - | 1 | - |

| 439 | 1.4510 | X3CrTi17 | 0.03 | 17.0-19.0 | 0.5 | - | 0.03 | 1 | Ti [0.20+4(C+N)] to 1.10Al .15 max. |

| 2205 | 1.4462 | X2CrNiMoN2253 | 0.03 | 22.0-23.0 | 4.5-6.5 | 3.0-3.5 | 0.14-0.20 | 2 | - |

| 2507 | 1.4410 | X2CrNiMoN2574 | 0.03 | 24.0-26.0 | 6.0-8.0 | 3.0-5.0 | 0.24-0.32 | 1.2 | - |

| s32760 | 1.4501 | X2CrNiMoCuWN | 0.03 | 24.0-26.0 | 6.0-8.0 | 3.0-4.0 | 0.20-0.30 | 1 | W 0.50-1.00 |

| 1.4529 | - | X1NiCrMoCuN | 0.02 | 20 | 25 | 6.5 | 0.15 | - | Cu 1.0 |

| 1.4362 | - | X2CrNiN23-4 | 0.02 | 23 | 4.8 | 0.3 | - | - | - |

| 254SMO | 1.45475 | 42CrMo4 | 0.01 | 20 | 18 | 6.1 | 0.02 | - | - |

Packaging and transportation

Packaging and transportation

Product certificate

APPLICATION FIELD

Our main manufactures are stainless steel, galvanized steel, carbon steel and etc. That apply to engineering, coal mine, textile, electric power, boiler, machinery, We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. We′re pleased to get your Inquiry and we will come back to as soon as possible.

mechanical

boiler plant

power plant

Chemical plant

Oil Pipelines

refrigeration equipment

Water pipes

Bearing

chemical plant

Natural Gas Pipeline

RELATED PRODUCTS

Get a Free Quote