304 Stainless Steel Pipe

Product Details

| Name | Stainless Steel Pipe |

| Thickness | 0.24-3mm |

| Outer diameter | 8-219mm |

| Length | 1-6m or according to customer's request |

| Standard | ASTM JIS AISI GB DIN EN |

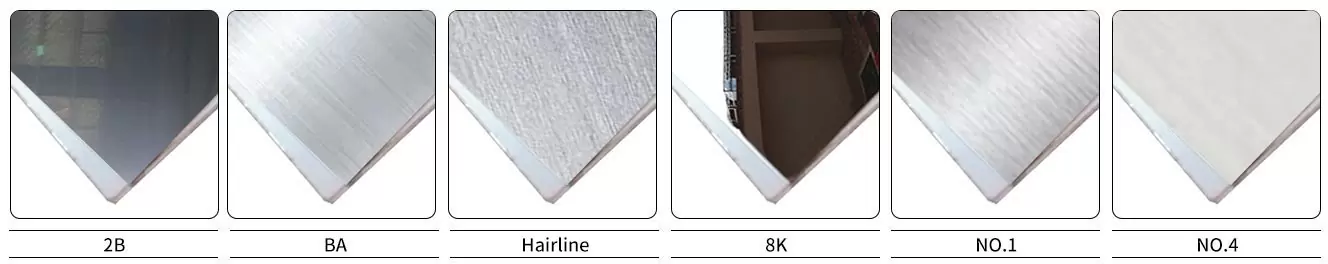

| Surface Finished | BA, 2B,NO.1, NO.4, 4K, HL ,8K |

| Certification | ISO, SGS, BV |

| Technique | Hot rolled or cold drawing |

| Edge | Mill Edge /Slit Edge |

| Quality | SGS Inspection |

| Main market | Asia/Europe/ South America |

| Delivery time | Within 7-10 Working Days |

| Payment Terms | T/T L/C and Western Union etc. |

| Finish | Description | Thickness (mm) | Width (mm) |

| 2B | Smooth finish, reflective grey sheen.Most widely used surface finish. | 0.55 | 914 & 1219 |

| Bright Annealed (BA) | Cold rolled, annealed in a controlled atmosphere to retain a highly reflective finish. | 0.70 | 914 & 1219 |

| Dull Polish (DP) | Selected for ease of cleaning, brushed look, non-reflective, used extensively in the catering industry, also push plates and kickplates. | 0.90 | 750, 914 & 1219 |

| Hot Rolled (HR) | Scaled finish, ideal if surface finish is not a key concern. | 1.20 | 750, 914, 1050, 1219 & 1500 |

| No.1 | Finished by hot-rolling,annealing and pickling, characterized by white pickled surface | 1.50 | 914, 1219 & 1500 |

| HL | finished by continuous liner polishing | 1.60 | 914, 1219 & 1500 |

| No.4 | polishing with No.150 to No.180 mesh | 2.00 | 914, 1219 & 1500 |

| No.8 | a mirror-like reflective surface by polishing | 2.50 | 914, 1219 & 1500 |

Chemical Composition

| Grade | W.nr | DIN | C | Cr | Ni | Mo | N | Mn | Other |

| 201/201L | - | - | 0.15 | 16.0-18.0 | 3.50/5.50 | - | 0.25 | 5.5-7.5 | 0.25N |

| 301 | 1.4310 | X12CrNi177 | 0.15 | 16.0-18.0 | 6.00/8.00 | - | 0.1 | 2 | - |

| 303 | 1.4305 | X12CrNi188 | 0.15 | 17.0-19.0 | 8.00/10.00 | 0.60* | 0.1 | 2 | - |

| 304 | 1.4350 | X5CrNi189 | 0.08 | 18.0-20.0 | 8.00/10.50 | - | 0.1 | 2 | - |

| 304L | 1.4306 | X2CrNi1911 | 0.03 | 18.0 - 20.0 | 8.0-12.0 | - | 0.1 | 2 | - |

| 321 | 1.4541 | X10CrNiTi189 | 0.08 | 17.0-19.0 | 9.0-12.0 | - | 0.1 | 2 | Ti 5x(C+N) |

| 316 | 1.4435 | X2CrNiMo1812 | 0.08 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | 0.1 | 2 | - |

| 316L | 1.4436 | X2CrNiMo1812 | 0.03 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | 0.1 | 2 | - |

| 309 | 1.4828 | X15CrNiSi2012 | 0.08 | 22.0-24.0 | 12.0-15.0 | - | - | 2 | - |

| 310S | 1.4845 | X12CrNi2521 | 0.08 | 24.0-26.0 | 19.0-22.0 | - | - | 2 | - |

| 904L | 1.4539 | X2NiCrMoCu25205 | 0.02 | 19.0-23.0 | 23.0-28.0 | 4.00-5.00 | 0.1 | 2 | - |

| 409 | 1.4512 | X6CrTi12 | 0.03 | 10.5-11.7 | 0.5 | - | 0.03 | - | Ti 6x(C+N) to .50 |

| 430 | 1.4016 | X8Cr17 | 0.12 | 16.0-18.0 | 0.75 | - | - | 1 | - |

| 439 | 1.4510 | X3CrTi17 | 0.03 | 17.0-19.0 | 0.5 | - | 0.03 | 1 | Ti [0.20+4(C+N)] to 1.10Al .15 max. |

| 2205 | 1.4462 | X2CrNiMoN2253 | 0.03 | 22.0-23.0 | 4.5-6.5 | 3.0-3.5 | 0.14-0.20 | 2 | - |

| 2507 | 1.4410 | X2CrNiMoN2574 | 0.03 | 24.0-26.0 | 6.0-8.0 | 3.0-5.0 | 0.24-0.32 | 1.2 | - |

| s32760 | 1.4501 | X2CrNiMoCuWN | 0.03 | 24.0-26.0 | 6.0-8.0 | 3.0-4.0 | 0.20-0.30 | 1 | W 0.50-1.00 |

| 1.4529 | - | X1NiCrMoCuN | 0.02 | 20 | 25 | 6.5 | 0.15 | - | Cu 1.0 |

| 1.4362 | - | X2CrNiN23-4 | 0.02 | 23 | 4.8 | 0.3 | - | - | - |

| 254SMO | 1.45475 | 42CrMo4 | 0.01 | 20 | 18 | 6.1 | 0.02 | - | - |

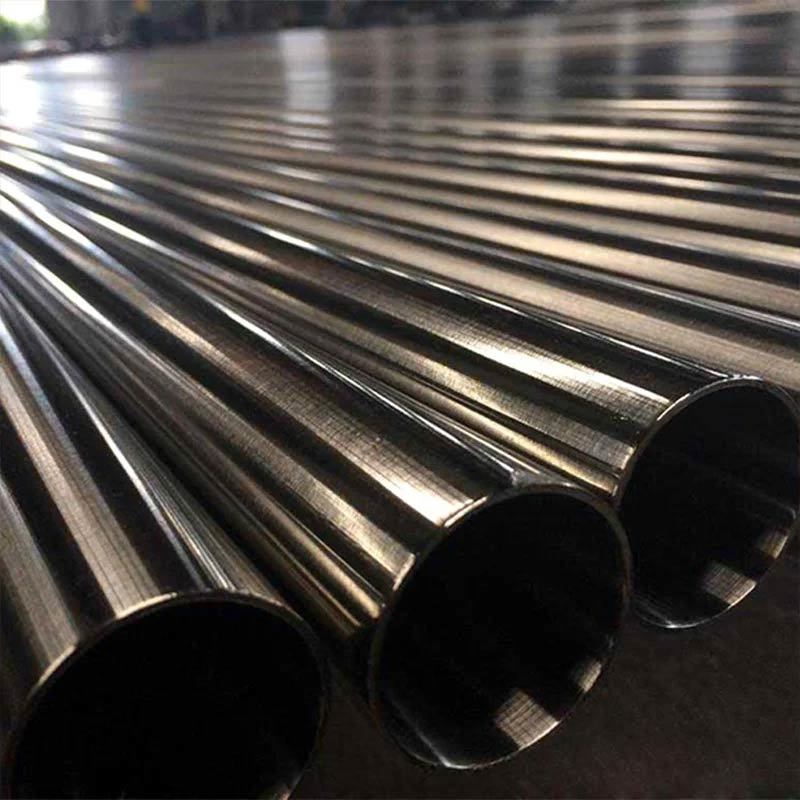

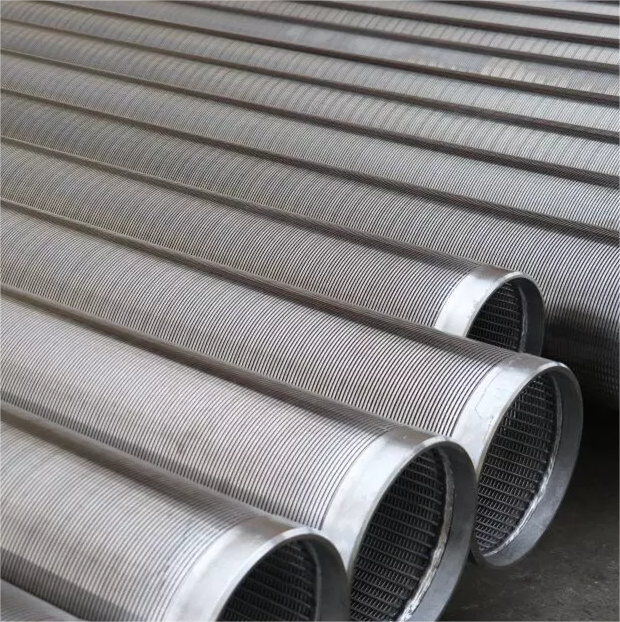

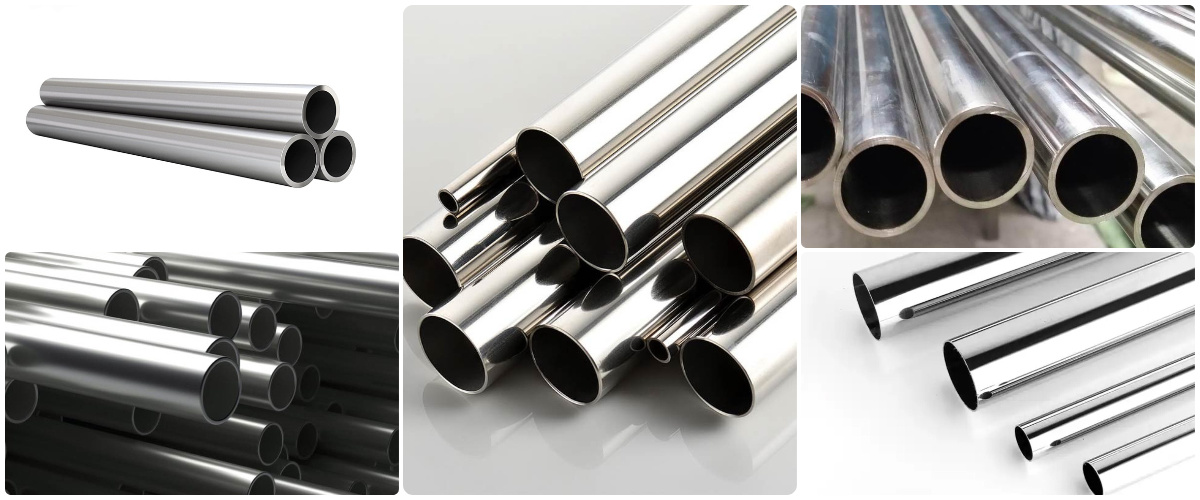

Product Presentation

Stainless steel pipes are corrosion-resistant metal tubes with high durability and strength. They are widely used in construction, chemical processing, food processing, aerospace, and more. Stainless steel pipes offer benefits such as corrosion resistance, high temperature resistance, and durability. They are manufactured through processes like seamless or welded techniques and come in various sizes and grades to suit different applications. Stainless steel pipes are used for water systems, conveying corrosive fluids, pharmaceutical equipment, and more, making them versatile in industries requiring reliability and longevity.

Stainless steel pipes are essential components in various industries due to their remarkable properties. Here's a more detailed overview:

Benefits:

- Corrosion Resistance: Stainless steel pipes resist corrosion, rust, and staining, making them ideal for harsh environments and corrosive substances.

- High Temperature Resistance: They can withstand high temperatures without deformation or deterioration, ensuring stability in extreme conditions.

- Durability: Stainless steel pipes are highly durable and long-lasting, offering excellent service life even in demanding applications.

- Hygienic: They are easy to clean and maintain, making them suitable for industries with strict hygiene requirements such as food processing and pharmaceuticals.

Manufacturing Techniques:

- Seamless: Seamless stainless steel pipes are manufactured without welding seams, providing uniformity in structure and enhanced strength.

- Welded: Welded stainless steel pipes are produced by welding stainless steel plates or coils, offering cost-effective solutions for various applications.

Applications:

- Construction: Stainless steel pipes are used in construction for plumbing, structural support, and architectural features due to their strength and corrosion resistance.

- Chemical Processing: They are employed in chemical processing plants for transporting corrosive chemicals and liquids safely.

- Food Processing: Stainless steel pipes are crucial in the food industry for conveying food products and maintaining hygiene standards.

- Aerospace: They find applications in aerospace engineering for fuel and hydraulic systems due to their lightweight nature and resistance to corrosion.

- Oil and Gas: Stainless steel pipes are utilized in the oil and gas industry for pipelines, offshore platforms, and refineries due to their resistance to corrosion and high-pressure capabilities.

- Pharmaceuticals: They are used in pharmaceutical manufacturing equipment where cleanliness, corrosion resistance, and sterility are critical.

Suitable Industries:

- Chemical Industry: Chemical plants and refineries use stainless steel pipes for their corrosion resistance and chemical compatibility.

- Food and Beverage Industry: Stainless steel pipes are prevalent in food processing plants and breweries for their hygienic properties and ease of cleaning.

- Construction Industry: They are used in building infrastructure, including water supply systems, structural supports, and architectural features.

- Medical Industry: Stainless steel pipes are utilized in medical equipment and devices for their biocompatibility and resistance to corrosion from sterilization processes.

In summary, stainless steel pipes offer a combination of corrosion resistance, durability, and versatility, making them indispensable in various industrial sectors.

Product Picture

Packaging and transportation&Customer feedback

Product Certificate

Shandong Chengshun Metal Materials Co., Ltd.is a comprehensive company dealing in high-quality steel products, with a superior geographical location and very convenient transportation. The company has a complete and scientific quality system, and has been recognized by the industry for its integrity, strength and product quality. Always adhere to the tenet of high quality, low cost, fast pace and excellent service. Our products have passed the "IS09001" qualtly system cerification, own CE cerificate and SGS test report.

APPLICATION FIELD

Our main manufactures are stainless steel, galvanized steel, carbon steel and etc. That apply to engineering, coal mine, textile, electric power, boiler, machinery, We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective. We′re pleased to get your Inquiry and we will come back to as soon as possible.

mechanical

power plant

chemical plant

Oil Pipelines

Natural Gas Pipeline

refrigeration equipment

boiler plant

Chemical plant

Water pipes

Bearing

RELATED PRODUCTS

Get a Free Quote